Powder metallurgy (PM) is a versatile manufacturing process involving the compaction and sintering of metal powders to create complex shapes near net-shape, minimizing material waste. This efficient and adaptable technology empowers diverse industries and holds immense potential for future growth. Let's explore the current market size, emerging trends, and forecasts for the powder metallurgy market through 2028.

Market Size and Growth:

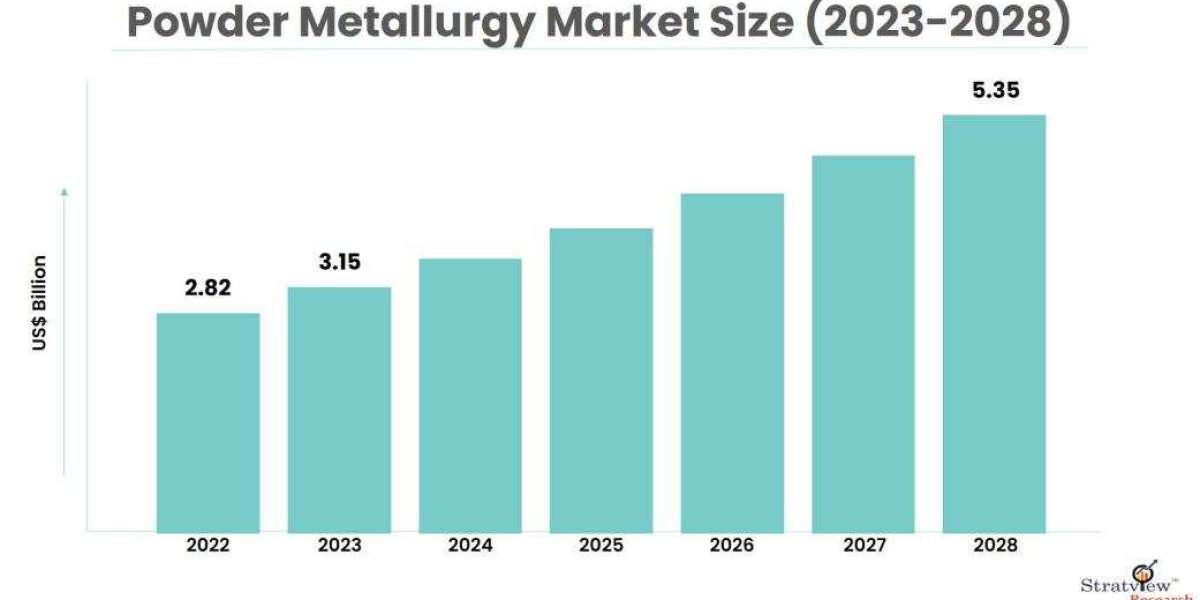

According to Stratview Research, the global powder metallurgy market size was valued at USD 3.15 billion in 2023 and it is projected to grow at a CAGR of 11.17% during the forecast period of 2023-2028. While 2020 presented temporary setbacks due to COVID-19, the market has demonstrably recovered and is poised for continued expansion.

Key Drivers:

Several factors are propelling the powder metallurgy market forward:

- Automotive Industry: This remains the largest driver, as PM components offer lightweighting, high strength, and near-net shapes, optimizing performance and fuel efficiency in vehicle design.

- Additive Manufacturing (3D Printing): Metal powders play a crucial role in this rapidly evolving technology, enabling complex geometries and customized parts with minimal material waste.

- Medical Devices: PM's biocompatibility and ability to create porous structures make it ideal for implants and artificial joints, catering to the growing demand for advanced medical solutions.

- Aerospace Defense: High-performance materials achievable through PM cater to the stringent requirements of aircraft and spacecraft components, leading to weight reduction and enhanced functionality.

- Electronics Consumer Goods: PM offers cost-effective production of small, intricate components for electronics and consumer products, driving market penetration.

Emerging Trends:

- Advanced Powders: Development of specialized powders with improved properties like higher purity, finer size, and enhanced control over shape and microstructure will offer superior performance and expand application possibilities.

- Additive Manufacturing Developments: Innovations in binder jetting, metal cold spray, and laser powder bed fusion are pushing the boundaries of 3D printing, creating new opportunities for PM integration.

- Sustainability Focus: The ability to use recycled materials and minimize waste makes PM an attractive choice for environmentally conscious manufacturers, aligning with the growing emphasis on sustainability.

Challenges and Restraints:

Despite its potential, the powder metallurgy market faces certain challenges:

- Fluctuating Raw Material Prices: Volatile prices of metal powders can impact production costs and profitability, requiring flexible sourcing strategies.

- High Initial Investment: Setting up PM facilities requires significant investment in equipment and expertise, creating a barrier for new entrants.

- Competition from Conventional Manufacturing: Established methods like casting and machining can be more cost-effective for simple shapes, necessitating continuous innovation in PM to offer unique value propositions.

Regional Variations:

The powder metallurgy market exhibits regional variations:

- North America: Holds the largest market share due to its mature automotive and aerospace industries.

- Europe: Follows closely with strong demand from automotive and medical device sectors.

- Asia Pacific: Shows rapid growth potential driven by expanding automotive and consumer goods industries.

- Rest of the World: Expected to exhibit steady growth, primarily in emerging economies with developing manufacturing sectors.

Forecast and Projections:

The future of the powder metallurgy market appears bright. With constant advancements in technology, expanding applications, and increasing environmental awareness, PM is poised to play a vital role in the future of manufacturing.

Conclusion:

The powder metallurgy market offers a dynamic and promising landscape. Understanding its current size, growth drivers, emerging trends, and challenges is crucial for stakeholders within the industry. By leveraging technological advancements, embracing sustainability, and catering to evolving market needs, powder metallurgy is well-positioned to secure its place as a vital manufacturing technology for the future.