Market Overview

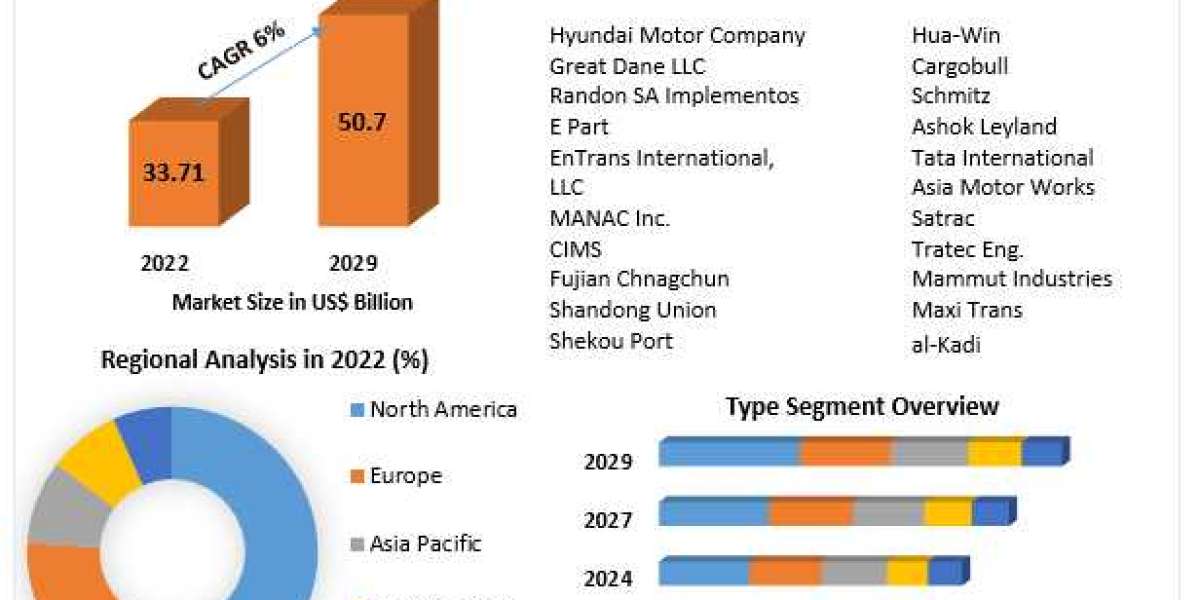

According to MRFR analysis, The size of vibration monitoring market is expected to reach USD USD 1.5 Billion by forecast 2030, with a CAGR of 6.5% during the forecast period. The worldwide vibration monitoring market's growth is primarily being driven by the widespread use of vibration monitoring systems in various industrial sectors as a significant component of their safety features during the assessment period. The enormous rise of the manufacturing and other industries brought on by quick industrialization and globalisation is driving the expansion of the vibration monitoring market globally. The advantages of vibration monitoring systems for spotting equipment faults and deterioration before they manifest other symptoms like lubricant impurity, high energy consumption, and others are fueling demand for advanced vibration monitoring systems and driving the growth of the global vibration monitoring market.

Regional Analysis

North America to Lead Vibration Monitoring Market

During the projection period, North America will lead the market. Growing adoption of technologically advanced solutions in various end use industries, an increase in the number of manufacturers offering vibration monitoring solutions, the presence of leading market players, increased RD activities, and the ease with which advanced technology can be adopted in various end use industries are all contributing to the region's global vibration monitoring market growth. Furthermore, increased usage in the United States contributes to market growth.

REQUEST FREE SAMPLE REPORT - https://www.marketresearchfuture.com/sample_request/3932

Key Players

The major players profiled by MRFR that are operating in the global vibration monitoring market are Honeywell International Inc. (the U.S.), Emerson Electric Co. (the U.S.), General Electric (the U.S.), Analog Devices Inc. (the U.S.), SKF AB (Sweden), National Instruments Corp. (the U.S.), Rockwell Automation, Inc. (the U.S.), Schaeffler Technologies AG Co. KG (Germany), Bruel Kiaer Sound Vibration Measurement A/S (Denmark), and Meggitt PLC (the U.K.), and others.

Introduction:

Vibration monitoring plays a crucial role in ensuring the smooth operation and longevity of various industrial machinery and equipment. With advancements in technology and the growing demand for efficient and reliable operations, the vibration monitoring industry has witnessed significant growth in recent years. In this blog post, we will delve into the fascinating world of vibration monitoring, exploring its key applications, market trends, and future prospects.

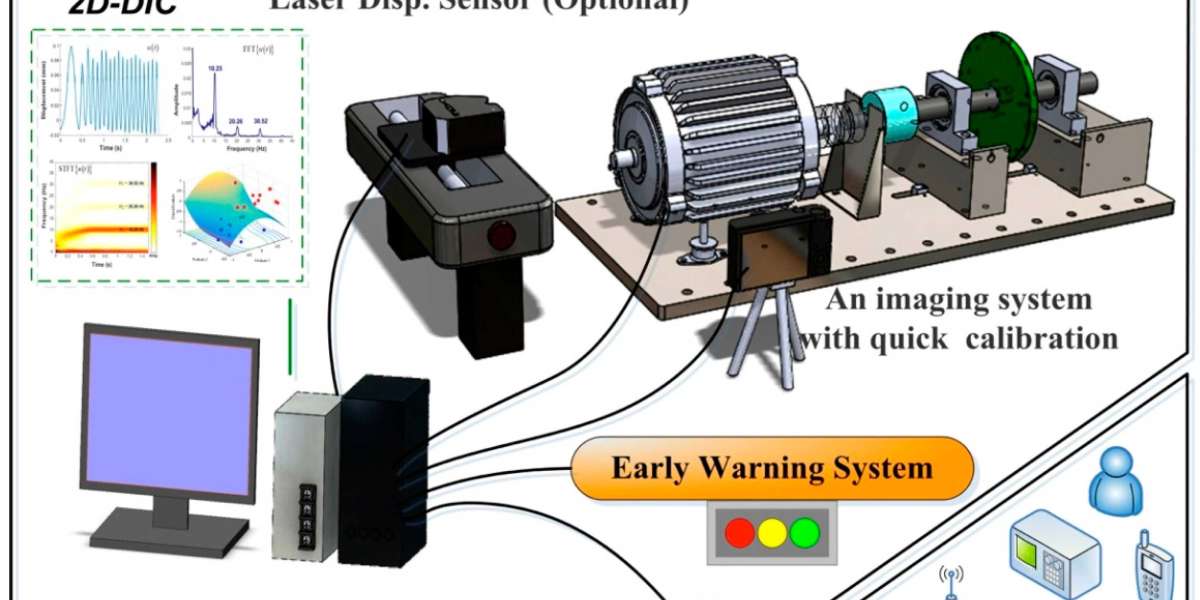

Understanding Vibration Monitoring:

Vibration monitoring involves the measurement and analysis of vibrations in machinery and structures to detect any abnormalities or potential faults. By continuously monitoring vibrations, engineers and technicians can identify early warning signs of equipment malfunctions, allowing for timely maintenance and minimizing the risk of costly breakdowns or accidents.

Key Applications of Vibration Monitoring:

- Manufacturing Sector: Vibration monitoring is extensively used in the manufacturing sector to monitor the health of critical machinery such as pumps, motors, compressors, and turbines. By detecting and analyzing vibrations, manufacturers can optimize maintenance schedules, reduce downtime, and enhance overall productivity.

- Oil and Gas Industry: The oil and gas industry heavily relies on vibration monitoring to ensure the reliable and safe operation of equipment, including pumps, generators, and drilling systems. By detecting potential faults or imbalances, vibration monitoring helps prevent catastrophic failures and ensures the uninterrupted flow of operations in this vital sector.

- Power Generation: Vibration monitoring is crucial in power generation facilities, including conventional power plants, wind farms, and hydroelectric stations. By continuously monitoring the vibrations in turbines, generators, and transformers, operators can detect irregularities and proactively address maintenance needs, maximizing efficiency and reducing downtime.

Market Trends and Growth Drivers: The vibration monitoring industry has experienced substantial growth, driven by several key factors:

- Technological Advancements: The integration of advanced technologies such as artificial intelligence (AI), machine learning (ML), and the Internet of Things (IoT) has revolutionized vibration monitoring systems. These advancements have enhanced the accuracy and efficiency of data collection, analysis, and predictive maintenance, leading to increased adoption across industries.

- Rising Focus on Preventive Maintenance: In today's competitive business landscape, organizations are increasingly adopting a proactive approach to maintenance. Vibration monitoring enables predictive maintenance, allowing businesses to identify potential issues before they escalate, minimize downtime, and optimize operational efficiency.

- Stringent Safety Regulations: Regulatory bodies across industries are enforcing stringent safety standards, mandating the implementation of vibration monitoring systems. Compliance with these regulations is driving the adoption of vibration monitoring solutions, especially in sectors such as oil and gas, power generation, and transportation.

Future Prospects: The future of the vibration monitoring industry looks promising, with several trends and developments on the horizon:

- Expansion of IoT-Enabled Solutions: The integration of vibration monitoring systems with IoT technology is expected to expand further. IoT-enabled devices can provide real-time data, remote monitoring capabilities, and predictive analytics, enabling businesses to make data-driven decisions and optimize equipment performance.

- Growth in Remote Monitoring: Remote monitoring solutions are gaining popularity, allowing organizations to monitor equipment vibrations from a central location. This trend is particularly beneficial for companies with multiple sites or large-scale operations, as it offers centralized control, reduces maintenance costs, and improves overall operational efficiency.

- Emphasis on Data Analytics and AI: As the volume of data collected by vibration monitoring systems continues to grow, the industry is placing greater emphasis on data analytics and AI. Advanced analytics tools and AI algorithms can process vast amounts of data, extract valuable insights, and enable more accurate predictions for predictive maintenance.

Related Reports:

Conclusion:

Vibration monitoring plays a vital role in ensuring the reliability, safety, and efficiency of industrial machinery across various sectors. With technological advancements, rising focus on preventive maintenance, and stringent regulations, the vibration monitoring industry is experiencing rapid growth. The future holds even more promise, with the expansion of IoT-enabled solutions, remote monitoring capabilities, and the integration of advanced data analytics and AI. As industries continue to prioritize efficient operations and minimize downtime, the demand for vibration monitoring solutions is set to soar, making it an exciting and vibrant industry to watch.