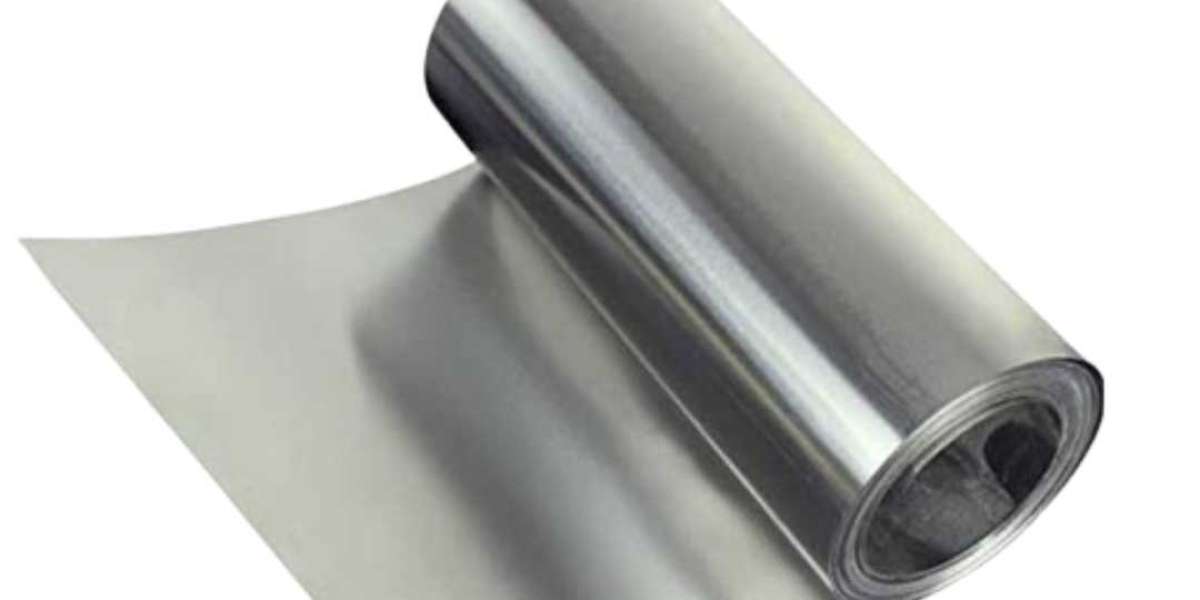

Aluminum foil sheets are one of the most versatile materials in both commercial and household applications. With their lightweight properties, superior durability, and remarkable adaptability, these sheets have become indispensable across industries and homes. Aluminum foil sheets offer a cost-effective, practical solution that caters to a range of needs, from packaging and insulation to cooking and crafting. This article delves into the exceptional qualities of aluminum foil sheets, their numerous applications, and their growing importance in industries worldwide, including India, which stands as a prominent hub for Aluminum sheet supplierand exporters.

Durability That Defies Expectations

Aluminum foil sheets might look delicate and flimsy at first glance, but their strength lies in their composition. These sheets are made from thin aluminum, a material renowned for its high tensile strength and resistance to corrosion. Despite their thinness, aluminum foil sheets can withstand a surprising amount of pressure and stress, making them ideal for packaging food, pharmaceuticals, and even delicate electronic components.

The durability of aluminum foil sheets also makes them suitable for industrial applications. For instance, their ability to withstand extreme temperatures—both hot and cold—ensures that they are perfect for insulation in HVAC systems. Similarly, their corrosion resistance makes them a preferred choice for protective coatings in automotive and aerospace industries. Aluminum sheet exporters emphasize these qualities, ensuring their global clientele gets a product that offers longevity and reliability.

Unparalleled Flexibility for Various Uses

What sets aluminum foil sheets apart from many other materials is their unmatched flexibility. They can be easily molded, folded, or shaped into any desired form without compromising their structural integrity. This feature is particularly beneficial in the food and packaging industry, where foil sheets are used to wrap and seal products of all shapes and sizes.

Furthermore, their reflective properties add another layer of functionality. Aluminum foil sheets are used in home kitchens as they help distribute heat evenly when baking or grilling. Similarly, their reflective surface plays a crucial role in insulating homes and offices, reducing heat transfer and cutting down on energy costs. This adaptability ensures that aluminum sheet suppliers can cater to a wide array of industries with a single product type, making it one of the most sought-after materials globally.

Everyday Applications That Make a Difference

Aluminum foil sheets are indispensable in everyday life. From wrapping leftovers to lining baking trays, their uses in the kitchen alone are virtually endless. They keep food fresh for longer periods by blocking moisture, air, and light, all of which contribute to spoilage. This feature is why they are widely used by restaurants, catering services, and households alike.

Outside the kitchen, aluminum foil sheets find a place in crafts and DIY projects. Their pliability makes them an excellent material for creating art pieces, ornaments, and other creative projects. Meanwhile, industries such as healthcare and pharmaceuticals rely on aluminum foil for sterile packaging, ensuring that medicines and medical equipment remain uncontaminated. In India, a growing number of aluminum sheet suppliers are catering to the rising demand for these versatile products in both domestic and international markets.

The Role of Aluminum Sheet Foil and Exporters in India

India has emerged as a significant player in the global aluminum industry, with numerous aluminum sheet suppliers and exporters driving the growth. The country's abundance of bauxite, coupled with advanced manufacturing facilities, has enabled Indian aluminum sheet manufacturers to produce high-quality products at competitive prices.

Indian Aluminum sheet exporterssupply a wide range of foil sheets tailored to meet the specific needs of international clients. Whether it’s foil sheets for food packaging or specialized sheets for industrial applications, exporters ensure that the products comply with international standards. Additionally, the country's strategic geographical location allows for efficient shipping to global markets, further enhancing its reputation as a reliable supplier.

Sustainability and Aluminum Foil Sheets

Another notable aspect of aluminum foil sheets is their eco-friendliness. Aluminum is one of the most recyclable materials, and recycling it consumes only 5% of the energy required to produce new aluminum. This makes aluminum foil sheets a sustainable choice for industries looking to minimize their carbon footprint. Many aluminum sheet suppliers are actively promoting recycling initiatives and educating their customers on the environmental benefits of using recyclable materials.

India, in particular, has seen a surge in demand for eco-friendly products. Aluminum sheets in India are increasingly being used in green building projects, where their energy efficiency and recyclability contribute to the overall sustainability of the construction. This trend highlights the importance of innovation and environmental awareness in the aluminum industry, ensuring that the material remains a relevant and valuable resource for years to come.

Challenges and Innovations in the Aluminum Foil Industry

Despite their numerous advantages, aluminum foil sheets do face certain challenges. For instance, their thin structure makes them prone to tearing during use. However, innovations in manufacturing technology have addressed this issue by developing stronger, more durable foil sheets without compromising their flexibility.

Another challenge is the competition from alternative materials such as plastic and paper. However, the growing awareness of environmental issues has led many industries to choose aluminum over less sustainable options. Aluminum sheet exporters and suppliers are leveraging this trend by focusing on the production of eco-friendly foil sheets that meet the demands of modern consumers.

Conclusion

Aluminum foil sheets have truly revolutionized the way we package, insulate, and create. Their unique combination of durability, flexibility, and everyday practicality makes them indispensable in both household and industrial settings. As Aluminum sheets in India continue to gain prominence, the country’s aluminum sheet suppliers and exporters are well-positioned to meet the growing global demand for this versatile material. From food preservation to industrial applications, aluminum foil sheets are proof that even the simplest materials can offer innovative solutions to complex challenges.

Frequently Asked Questions (FAQs)

1. What are the primary uses of aluminum foil sheets?

Aluminum foil sheets are primarily used for food packaging, insulation, cooking, and crafting. They are also extensively employed in industries such as healthcare, automotive, and construction for purposes like sterile packaging and heat insulation.

2. How are aluminum foil sheets eco-friendly?

Aluminum foil sheets are highly recyclable. Recycling aluminum consumes only a fraction of the energy required for producing new aluminum, making it a sustainable and eco-friendly material.

3. Why should I choose aluminum sheets from India?

Aluminum sheets in India are known for their high quality, affordability, and compliance with international standards. Indian aluminum sheet suppliers and exporters offer a wide range of products tailored to meet global industrial and consumer needs.