The global manufacturing analytics market, valued at approximately USD 5.5 billion in 2022, is poised for remarkable growth, projected to surge at a CAGR of 16.8% from 2023 to 2031, reaching an estimated USD 22.3 billion by the end of 2031. This growth trajectory underscores the pivotal role of manufacturing analytics in driving operational efficiency, quality improvement, and predictive maintenance within the manufacturing sector.

Driving Forces Behind Market Expansion

The manufacturing industry is under constant pressure to enhance operations and maintain a competitive edge. Manufacturing analytics solutions have emerged as critical tools, enabling manufacturers to collect and analyze vast amounts of production data. This data-driven approach helps identify inefficiencies, optimize processes, and reduce costs. For instance, studies show that adopting manufacturing analytics solutions can improve Overall Equipment Effectiveness (OEE) by up to 88%, highlighting the significant impact of these technologies on operational efficiency.

The rise in demand for real-time visibility into production processes is another key factor propelling market growth. Analytics-driven applications offer manufacturers insights that allow them to proactively address issues, ensuring zero accidents and zero defects. By leveraging these insights, manufacturers can improve safety and product quality, enhancing overall profitability.

The Impact of Industry 4.0

The advent of Industry 4.0 marks a transformative phase for the manufacturing sector. Characterized by the integration of digital technologies such as the Internet of Things (IoT), big data analytics, cloud computing, Artificial Intelligence (AI), and Machine Learning (ML), Industry 4.0 is reshaping traditional manufacturing processes. Smart factories, equipped with these advanced technologies, are becoming more efficient, productive, and responsive to market demands.

The rapid industrialization and automation of processes generate vast amounts of data. Manufacturing analytics solutions are essential for collecting, analyzing, and visualizing this data, enabling real-time, informed decision-making. The integration of AI and Radio Frequency Identification (RFID) further enhances the capabilities of manufacturing analytics, driving the development of smarter, more responsive production systems.

Regional Outlook and Market Dynamics

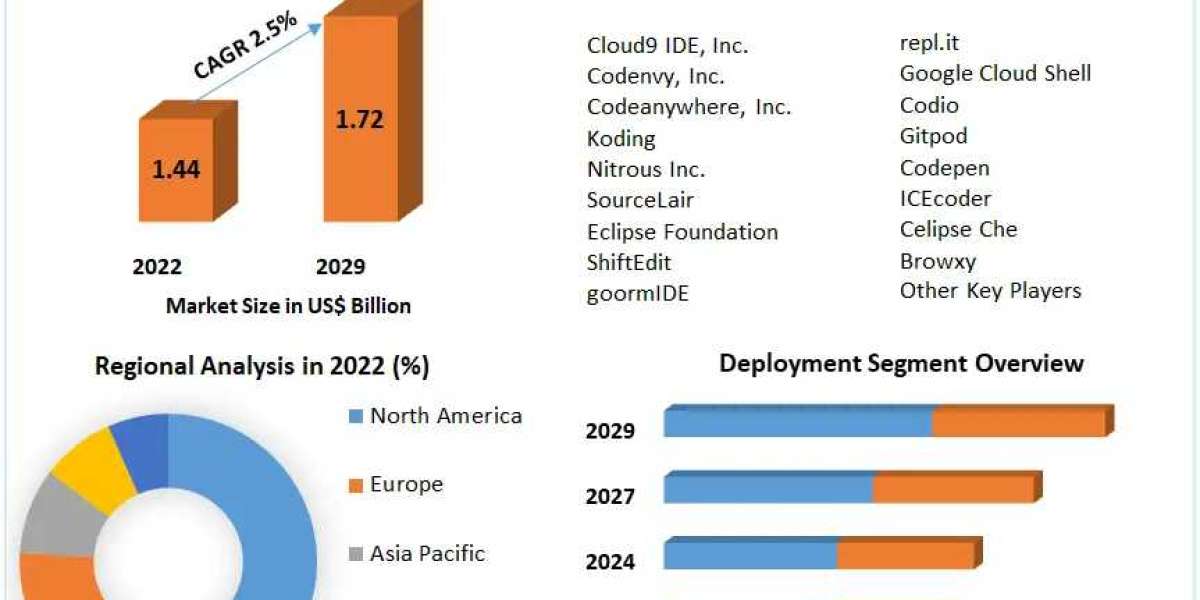

North America is expected to maintain a dominant position in the global manufacturing analytics market, driven by the extensive adoption of analytics tools and significant investments in RD of advanced manufacturing technologies. The region's robust technological infrastructure and focus on innovation contribute to its leading market share.

Meanwhile, the Asia Pacific region is projected to be the fastest-growing market for manufacturing analytics. The burgeoning demand for big data analytics in the manufacturing sector, coupled with rapid industrialization, is driving significant market growth in this region. Countries like China and India are at the forefront, investing heavily in digital transformation and analytics to enhance their manufacturing capabilities.

Leading Players in the Market

Key players driving the manufacturing analytics market include TIBCO (Cloud Software Group, Inc.), SAS Institute Inc., Sisense Inc., SAP SE, Alteryx, Inc., Tableau Software, Inc., Oracle Corporation, KNIME, GE Digital, QlikTech International AB, IBM Corporation, Infragistics, Northwest Analytics, Inc., Aegis Software, and Keysight Technologies, Inc. These companies are at the forefront of innovation, continuously developing advanced analytics solutions to meet the evolving needs of the manufacturing sector.