When it comes to materials that combine durability, versatility, and sustainability, HDPE sheets have emerged as a top choice in various industries. From packaging and construction to agriculture and healthcare, the adaptability of HDPE sheet plastic makes it an invaluable resource for countless applications. This article delves into the unique features of HDPE plastic sheets, their advantages, applications, and the reasons they are a sustainable choice for modern industries.

Understanding HDPE Sheets

HDPE, or High-Density Polyethylene, is a thermoplastic polymer known for its high strength-to-density ratio. HDPE sheets are produced by melting and molding polyethylene, resulting in lightweight, yet incredibly sturdy sheets. These characteristics make HDPE plastic sheets ideal for applications that require resistance to impact, moisture, and chemicals.

One of the most notable properties of HDPE sheet plastic is its ability to withstand harsh environmental conditions without degrading. This makes it a preferred material in industries that prioritize durability and long-term performance.

Advantages of HDPE Plastic Sheets

HDPE sheets stand out due to a wide range of benefits:

Durability: Plastic HDPE sheets are resistant to cracks, punctures, and wear and tear. They retain their structural integrity even in extreme conditions, such as high-impact applications or exposure to UV radiation.

Chemical Resistance: HDPE sheets are resistant to many chemicals, acids, and solvents, making them ideal for use in chemical storage, pipelines, and tanks.

Lightweight: Despite their toughness, HDPE plastic sheets are surprisingly lightweight, reducing handling and transportation costs.

Moisture Resistance: The non-porous nature of HDPE sheets ensures that they are impermeable to water, making them suitable for marine and outdoor applications.

Ease of Fabrication: HDPE sheets can be easily cut, welded, and molded into various shapes and sizes, making them a versatile choice for custom applications.

Recyclability: As an eco-friendly material, HDPE is 100% recyclable. It can be reprocessed into new products, reducing waste and conserving resources.

Common Applications of HDPE Sheets

Thanks to their versatility and strength, HDPE sheets are utilized in a myriad of industries:

Construction: HDPE plastic sheets are widely used in construction for creating barriers, wall linings, and protective surfaces. Their ability to resist moisture and chemicals makes them perfect for ground stabilization and waterproofing.

Agriculture: Farmers and agribusinesses use HDPE sheets for lining ponds, creating greenhouse covers, and constructing silos. Their durability ensures long-lasting performance even in challenging outdoor conditions.

Packaging: The lightweight and non-toxic properties of HDPE sheet plastic make it an excellent choice for food-grade containers and industrial packaging.

Healthcare: In the medical field, Plastic HDPE sheets are employed to manufacture prosthetics, medical equipment, and hygienic surfaces due to their non-reactive and easy-to-clean properties.

Automotive: HDPE sheets find applications in the automotive industry for producing fuel tanks, door panels, and protective covers due to their impact resistance and lightweight nature.

Signage and Advertising: With their ability to endure exposure to weather and UV light, HDPE plastic sheets are used for outdoor signage and display boards.

Marine Applications: The waterproof and UV-resistant properties of HDPE sheets make them ideal for dock fenders, boat flooring, and other marine equipment.

Why HDPE Sheets Are a Sustainable Choice

As the global demand for environmentally friendly materials increases, HDPE plastic sheets stand out as a sustainable solution. They offer the following ecological benefits:

Recyclability: HDPE is one of the most commonly recycled plastics. Used sheets can be reprocessed into new products, reducing waste and the need for virgin materials.

Longevity: The durability of HDPE sheets ensures a long lifecycle, reducing the frequency of replacement and the associated environmental costs.

Energy Efficiency: The production process of HDPE sheets consumes less energy compared to other plastics and materials.

Non-Toxicity: HDPE sheets are non-toxic and safe for applications involving food, water, and medical equipment, ensuring minimal environmental and health risks.

Reduced Landfill Waste: With proper recycling programs, HDPE sheets can avoid ending up in landfills, contributing to a circular economy.

Choosing the Right HDPE Sheets for Your Needs

Selecting the appropriate HDPE sheet plastic for your application requires consideration of various factors, such as thickness, size, and specific properties like UV resistance or color.

Thickness: Thicker sheets provide better structural integrity for heavy-duty applications, while thinner sheets are more suitable for lightweight and flexible uses.

UV Stabilization: For outdoor applications, opt for UV-stabilized HDPE sheets to ensure longevity under sunlight exposure.

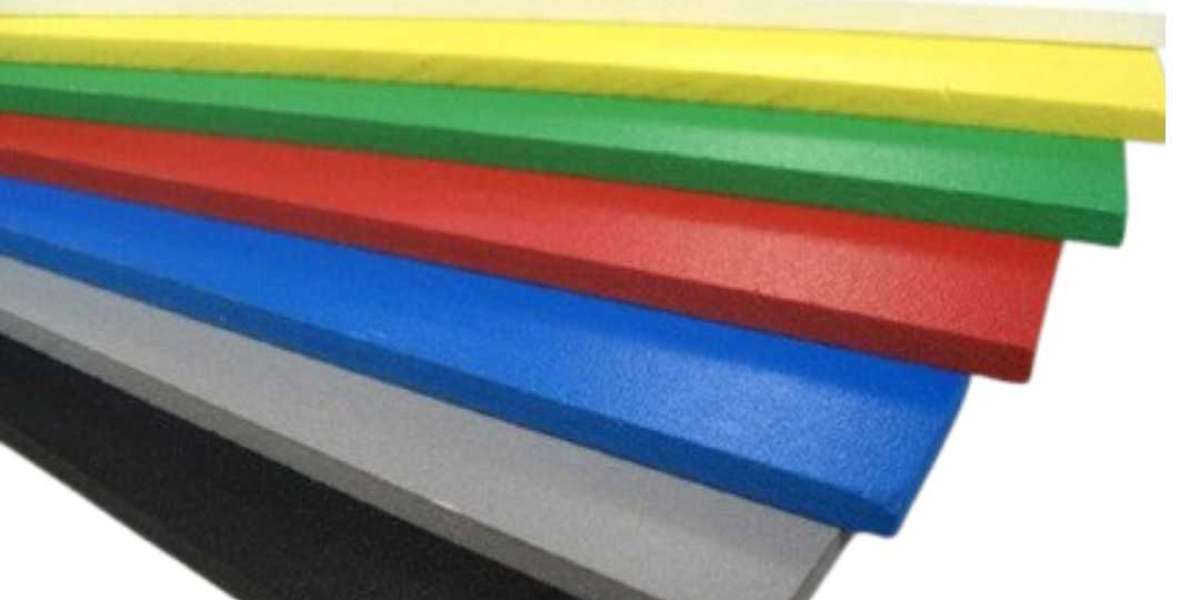

- Color: While natural or black HDPE sheets are common, colored sheets are available for aesthetic or specific functional purposes.

Custom Fabrication: Many manufacturers offer custom-cut HDPE plastic sheets tailored to unique project requirements.

Conclusion

HDPE sheets are a testament to the versatility and sustainability of modern materials. Their exceptional durability, lightweight nature, and resistance to environmental factors make them an indispensable choice for a variety of industries. As businesses and consumers increasingly prioritize eco-friendly solutions, HDPE sheet plastic stands out as a reliable, recyclable, and cost-effective material.

Whether you are in construction, agriculture, healthcare, or any other field, HDPE plastic sheets offer the perfect balance of performance and environmental responsibility. By choosing HDPE sheets, you invest in a solution that not only meets your needs but also contributes to a sustainable future.

Frequently Asked Questions

1. What are the key differences between HDPE sheets and other types of plastic sheets?

HDPE sheets are distinct due to their high strength-to-density ratio, chemical resistance, and durability. Unlike other plastics, HDPE sheets are highly resistant to moisture and environmental stress, making them ideal for outdoor and heavy-duty applications. Additionally, HDPE is fully recyclable, offering an eco-friendly advantage over many other plastics.

2. Can HDPE sheets be used for food-grade applications?

Yes, HDPE sheets are non-toxic and FDA-approved for food-grade applications. They are commonly used in food storage containers, cutting boards, and packaging solutions due to their hygienic and easy-to-clean surface.

3. How should HDPE sheets be maintained to ensure longevity?

HDPE sheets require minimal maintenance. Regular cleaning with mild soap and water is sufficient to keep them in good condition. For outdoor applications, UV-stabilized HDPE sheets should be used to prevent degradation from prolonged sunlight exposure. Avoid using harsh chemicals or abrasive tools to clean the surface, as this can cause scratches or damage.