Non-destructive inspection (NDI) equipment plays a crucial role in quality control and safety across various industries by allowing for the examination of materials and structures without causing damage. Utilizing technologies such as ultrasonic, radiographic, and infrared imaging, NDI equipment helps detect defects, inconsistencies, and potential failures in components and systems. As industries demand higher standards for safety and reliability, non-destructive inspection is increasingly vital for maintaining operational integrity and extending the lifecycle of critical assets.

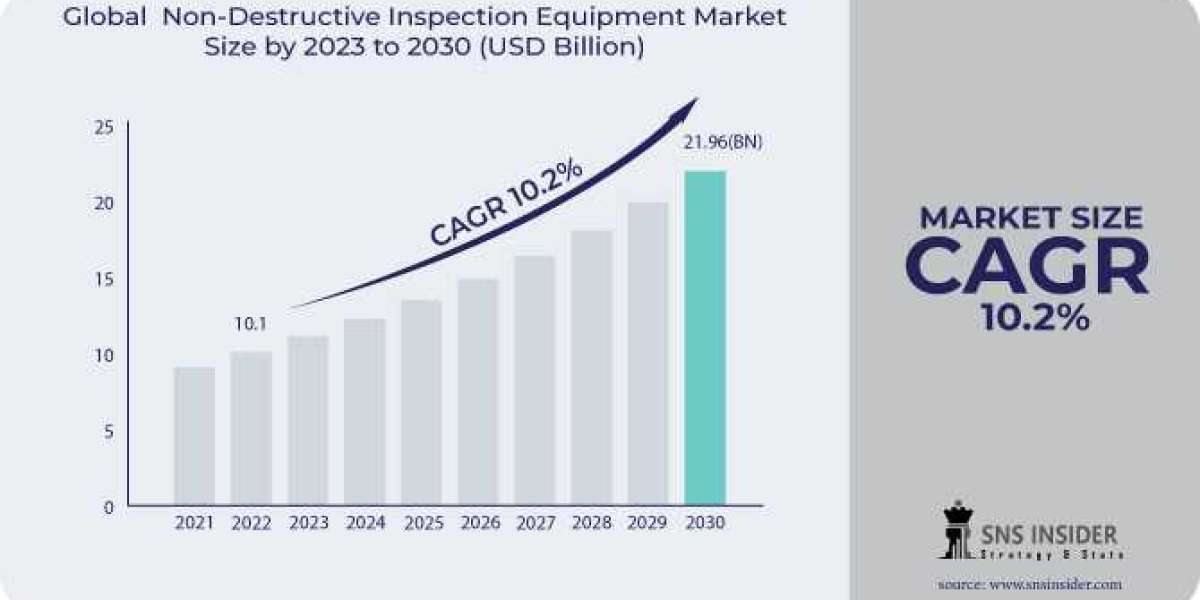

The Non-Destructive Inspection Equipment Market was valued at USD 10.1 billion in 2022 and is projected to reach USD 21.96 billion by 2030, with a compound annual growth rate (CAGR) of 10.2% during the forecast period from 2023 to 2030.

Future Scope:

The future of non-destructive inspection equipment is set to be characterized by advancements in technology and integration. Innovations such as advanced imaging techniques, enhanced sensor technologies, and AI-driven analysis are expected to improve detection capabilities and accuracy. The development of portable and automated NDI systems will facilitate on-site inspections and real-time monitoring. Additionally, the integration of big data and predictive analytics will enable more proactive maintenance strategies, further enhancing the effectiveness of non-destructive inspection.

Key Points:

- Enables examination of materials and structures without causing damage.

- Utilizes ultrasonic, radiographic, and infrared imaging technologies.

- Crucial for quality control and safety across various industries.

- Features advancements in imaging, sensor technology, and AI.

- Includes portable and automated systems for on-site inspections.

Trends:

Key trends in non-destructive inspection include the increasing use of AI and machine learning for enhanced data analysis and defect detection. The rise of portable and automated NDI systems is making on-site inspections more feasible and efficient. Advanced imaging technologies, such as digital radiography and phased array ultrasonics, are becoming more prevalent, providing greater accuracy and detail. Additionally, the integration of predictive analytics and big data is helping to shift maintenance strategies from reactive to proactive.

Application:

Non-destructive inspection equipment is applied in various sectors including aerospace, automotive, construction, and energy. In aerospace, it ensures the integrity of aircraft components and structures. Automotive industries use NDI for quality assurance and safety checks of vehicle parts. Construction and infrastructure sectors rely on NDI to inspect welds and concrete structures. The energy sector employs NDI to monitor pipelines, reactors, and other critical infrastructure.

Conclusion:

Non-destructive inspection equipment is essential for maintaining the safety, reliability, and quality of materials and structures. As technology continues to advance, these systems are becoming more sophisticated, offering improved accuracy, portability, and integration with other technologies. The ongoing innovations in NDI will enhance its effectiveness in ensuring the integrity of critical assets and supporting the operational needs of various industries.

Read More Details: https://www.snsinsider.com/reports/non-destructive-inspection-equipment-market-3628

Contact Us:

Akash Anand – Head of Business Development Strategy

Phone: +1-415-230-0044 (US) | +91-7798602273 (IND)