plant based starch cutleries and manufacturing professional training goal is to develop in all aspects of morality, intelligence, physical, beauty, etc., cultivate good professional quality, facing the manufacturing industry, Engaged in mold design, mold processing technology production, stamping and plastic forming processing, CNC machine tool operation and production management and other work of advanced technical application professionals, then, we will understand the design points of plant based starch cutleries.

A, plant based starch cutleries in the beginning of the design of each injection molding product, first determine its opening direction and parting line, as far as possible to reduce the core pulling slider mechanism, to ensure that the parting line to eliminate the impact on the appearance.

1. After the mold opening direction is determined, the product bars, fasteners, protrudes and other structures are designed as much as possible to be consistent with the mold opening direction, avoid centering, reduce stitches, and extend the service life of the mold.

2, after the opening direction is determined, the appropriate parting line can be selected to make the opening direction without gap and improve the appearance and performance.

Two, plant based starch cutleries drawing slope

1, moderate drawing inclination can avoid product hair (drawing). The release gradient of the smooth surface should be greater than 0.5 degrees, the surface of the fine grain (sand) should be greater than 1 degree, and the surface of the coarse grain should be greater than 1.5 degrees.

2, the appropriate drawing inclination can avoid the top of the product scratches, such as top white, top deformation, top damage.

3, the deep cavity structure of the product requires the outer surface slope as much as possible greater than the inner surface slope, to ensure that the mold core is good position during injection molding, obtain uniform product wall thickness, and ensure the material strength of the product opening.

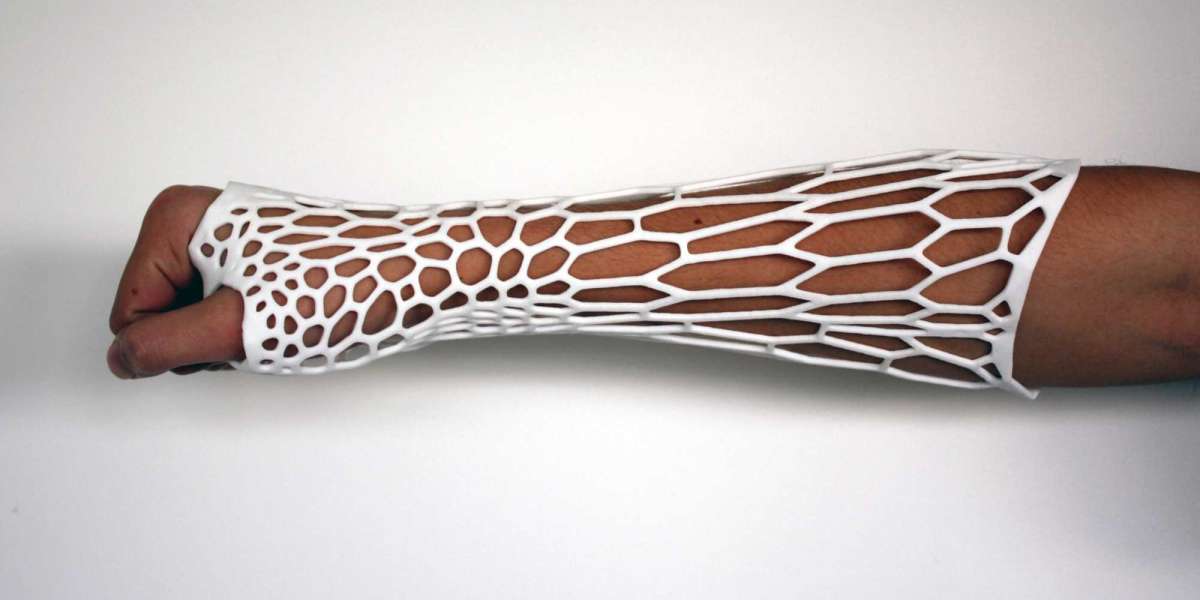

Third, plant based starch cutleries product wall thickness

1, a variety of plant based starch cutleries have a certain range of wall thickness, generally 0.5~4mm. The wall thickness of more than 4mm will cause the cooling time is too long, shrinkage and other problems, so it should be considered to change the product structure.

2, uneven wall thickness will cause surface shrinkage.

3, uneven wall thickness will cause porosity and welding.

Four. Reinforcing tendons

1, the reasonable application of reinforcement can improve product rigidity and reduce deformation.

2, the thickness of the reinforcement should be (0.5~0.7) t product wall thickness. Otherwise, it will cause surface shrinkage.

3. The slope of one side of the reinforcement is greater than 1.5 to avoid top injury.

5. Round corners

1, the rounded corner is too small may cause product stress concentration, resulting in product cracking.

2. Too small rounded corner may cause stress concentration in the mold cavity, resulting in cavity rupture.

3, set a reasonable rounded corner, can also improve the mold processing technology. For example, the cavity can be milled directly with the r tool, avoiding inefficient electrical machining.

4, different rounded corners may cause the parting line to move, need to choose different rounded corners or clear corners according to the actual situation.

Six, holes

1, the shape of the hole as simple as possible, generally should be taken round.

2. The axis of the opening hole is consistent with the direction of the opening mold, which can avoid centering.

3, when the hole width ratio is greater than 2, the drawing inclination should be set. In this case, the hole diameter should be calculated using the small path size (up to the large solid size).

4, the blind hole length-diameter ratio is generally not more than 4. Hall needle valve punching, hole and product edge distance is generally greater than the aperture size.

1. When the plastic parts can not release smoothly along the mold opening direction, the core pulling sliding mechanism should be designed. The slider of the suction mechanism can form complex product structure, but it is easy to cause defects such as product suture line and shrinkage, increase the cost of the mold and shorten the life of the mold.

When designing plant based starch cutleries, if no special requirements, try to avoid the core pulling structure. The axial direction of the hole and the direction of the rib are changed to the opening direction, and the die core of the cavity is used for blanking.

plant based starch cutleries https://www.plasticsproduct.com/Starch_based_eco_cutleries